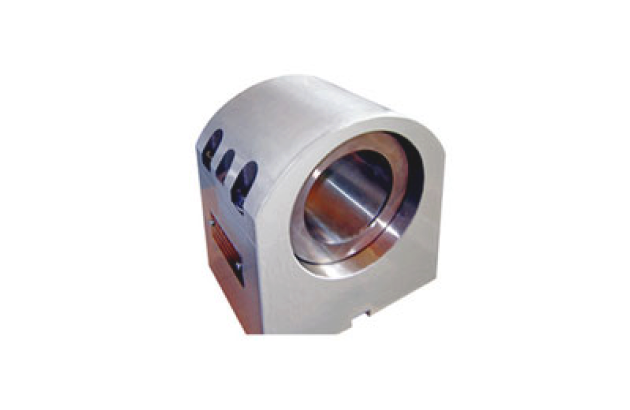

End Casting

“End Casting” refers to end parts made by a casting process. These parts are typically used in mechanical or industrial systems as end components and serve a variety of roles such as supporting, connecting, or terminating a structure or system.

Applications:

Piping and Fluid Transmission Systems:

End castings are used as caps, connectors, or support bases in piping systems.

Industrial Machinery and Equipment:

In industrial equipment, End Casting is used to create a base, frame, or housing for the end parts of a machine.

Automotive Parts:

In automotive powertrain or suspension systems, these parts are used as end connections for added stability and to connect various parts.

Metal and Mechanical Structures:

In structures such as bridges or metal buildings, end castings are used to reinforce or complete the structural design.

Features:

High strength:

They are usually made of durable materials such as steel, aluminum, or cast iron to withstand high pressure and load.

Complex design capability:

The casting process allows the production of complex and special shapes for a variety of applications.

High durability:

These parts are designed to withstand harsh environmental conditions, such as high temperatures, abrasion, and corrosion.

Customization:

Depending on the need, End Casting can be manufactured with specific dimensions and specifications.

Conclusion:

End Casting parts play an important role in various industries due to their flexibility in design and high durability. The use of these parts improves performance, reduces maintenance costs, and increases the lifespan of industrial and mechanical systems.